Rotometals.com

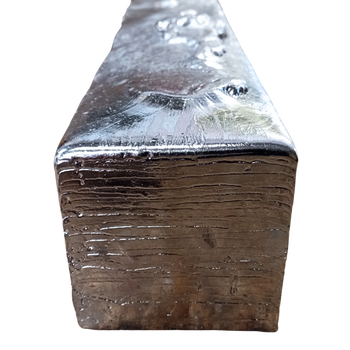

Lead Free Bullet Casting Alloy Bismuth based

- SKU:

- Leadfreebulletalloy

- MPN:

- 547735

- Availability:

- in stock

- Weight:

- 1.00 LBS

- Shipping:

- Calculated at Checkout

Bulk discount rates

Below are the available bulk discount rates for each individual item when you purchase a certain amount

| Buy 15 - 49 | and get 5% off |

| Buy 50 - 99 | and get 7% off |

| Buy 100 - 249 | and get 9% off |

| Buy 250 - 499 | and get 16% off |

Description

The bismuth gives you the weight (as close to lead as possible) and the tin helps holds it together and makes it less brittle. This is an alloy we have been asked to make a few times so we decided to make a larger batch and have it easily available to everyone. As we are still testing this alloy, we are offering it at a lower cost and asking customers for feedback and their thoughts on how it works. Yes, we know it costs way more then a lead version, but hopefully with more volume, we can offer better prices in the future. One item of feedback we got from our customer follows:

@ 2400 fps in my 30'06, but has lost 29% of nominal cast bullet weight

19 Reviews

-

Bullet Bismuth

I use it to make jig heads for my customers at Glasswater Angling as we are a lead free, non lead, fishing tackle company. It provides a specific gravity close to lead and is very easy to work with. I have gone through 15lbs of it (over 2,000 jig heads) and have found it consistent every time.

-

Bismuth Tin Alloy

I have been using the Bismuth Tin alloy to pour all types of lead free jig heads and blade baits in my molds from Do-iT Molds. Its a perfect alloy for this purpose!!!

-

Lead free alloy

I bought this alloy to cast for muzzleloaders and shotgun for hunting in an area that prohibits lead. So far it casts well but definitely prefers lower temperatures than lead alloys, and casts better in colder molds.

-

Lead free bullet alloy

It's more expensive than lead but not nearly as hazardous. Good finished weight and melts without a problem. I bought 15 pounds and it came in a few days, less than a week. Good stuff!

-

5 star product

Best products for all purpose

-

Lead Free Bullet Casting Alloy (88%-Bismuth, 12%-tin)

This alloy worked out perfectly for me! I needed a Lead-Free alloy that I could easily pour using the same bait molds I purchased from Do-IT Molds. No issues at all, environmentally safer than lead and I would suggest / recommend this alloy to anyone else pouring baits!!!

-

Bismuth/tin bullet alloy.

I have been quite frustrated wanting my father’s custom .64 caliber cap and ball rifle to be able to hunt in California. All projectiles must be 0% lead. I can now hunt using this awesome alloy. Thanks

-

Lead Free Bullet Casting Alloy (88%-Bismuth, 12%-tin)

A speedy doorstep delivery in my case VIA FedEx as I live way up in the Sierra Nevada Mountains West of Yosemite National Park. All Items ordered were well packaged and were remarkably accurate as to their advertised weight. I had spent a good deal of time browsing the Rotometals Web page where found a treasure-trove of valuable data on their products. Highly recommended and I will continue to do business with them.

-

Casting a .530 round ball with a lee double cavity mold

Cast round ball from a Lee .530 double cavity mold using a Lee Precision production pot IV. I too had a bit of trouble finding the right temp but once I found it the balls came out easily from the mold with a slight tap looking fairly good. This was a first time casting my own round ball so with time they will most likely look much better. Think I did pretty good for the first time. The hard part is keeping the right temp with the equipment I had. Each time I opened the mold I had my fingers crossed but there is not much choice here in California. I will be trying them out on the range in a couple of weeks so I will return and let you all know how they were and will have my fingers crossed there too. Thanks for coming up with something that will allow the sport to continue here. Hope this is the answer.